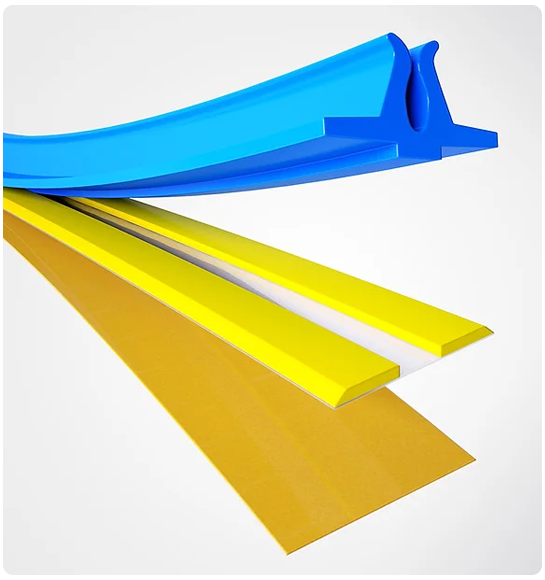

Creasing matrix was created as a solution to aid easier set-up of a die-cutter and creasing template layout. Creasing matrix is a system that self-aligns the creasing matrix base with the creasing rule therefore it provides a perfectly registered crease to solid or corrugated board. Before the use of creasing matrix, the process was set-up by hand in a method that is extremely time consuming.

Creasing matrix are essential in today's requirements for fast preparation and high production on automatic folder & gluer machine without any stoppage. Creasing matrix reduces downtime of the die-cutting machine by enabling assured accurate location of the creasing rule.

Our best-selling matrix worldwide! The perfect balance between cost and performance.

XTC is a plastic matrix that is low cost and durable; suitable for use on any type of machine. Channel XTC is the most cost-effective matrix system ever.

Our Word isn't enough! Try our free sample and decide for yourself!

Pink is the result of years of R&D with our engineers and marketing specialists based on requests from our customers for a matrix which is both extra durable but also easy to skive.

Manufactured from the patented “Rosadium” material, this product gives you the confidence to use Pink for long run applications.

A revolutionary creasing matrix designed specifically for corrugated boards.

The Reverse Bend solution from C&T allows the board to be creased from the reverse side, eliminating cracking and allowing the creation of a concertina fold in a single pass.

Using an off-centre matrix allows double creasing and where creasing rule and cutting rule are close together. When you have a ready Off-centre matrix, punching operator need not cut the standard matrix to get the off center.

You don’t have to wait for great things to happen! Take your first step into the league of greatness!

You don’t have to wait for great things to happen! Take your first step into the league of greatness!